Project Description

CONVERSIONS-RETROFITTING

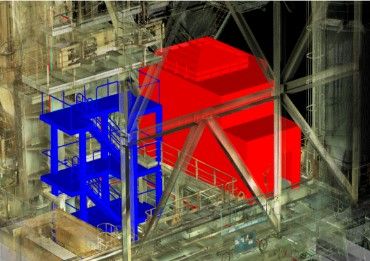

PROJECT: MONTE URQUIOLA/MONTE ULÍA Scrubber Ready Notation

Approval Engineering Scrubber Ready Notation from Bureau Veritas of the installation of a scrubber for the treatment of exhaust gases from the main engines and auxiliary engines of the Crude Oil Tankers “Monte Urquiola” and “Monte Ulía”

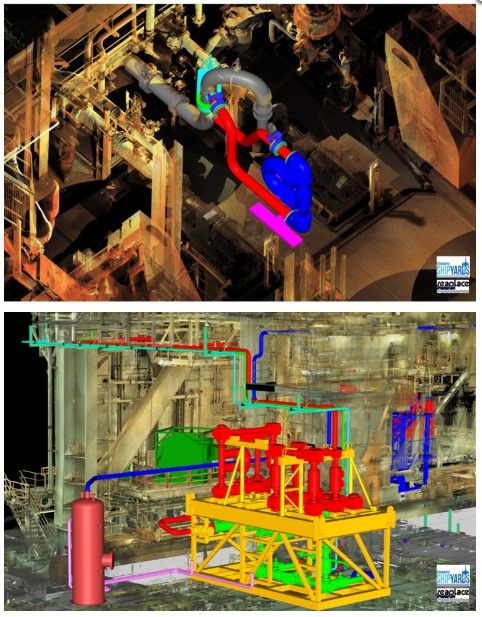

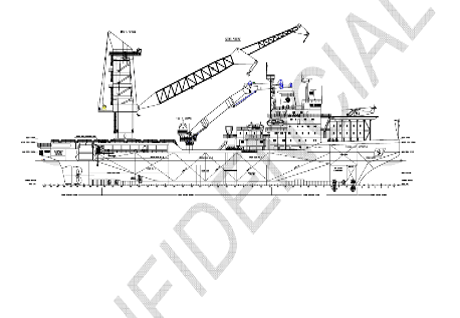

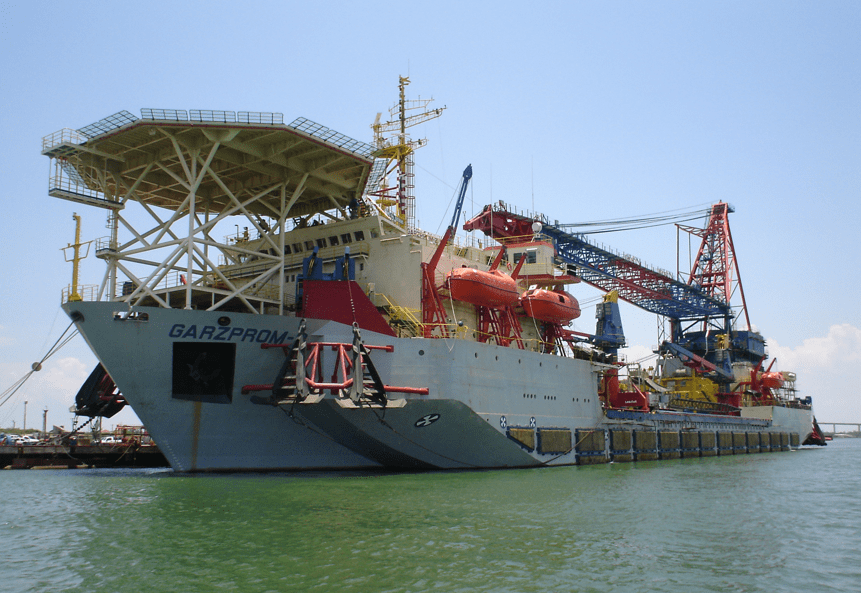

PROJECT: Ultradeep water rated Drillship second BOP installation and MPD upgrade

Engineering works for:

- The installation of an MPD (Managed Pressure Drilling). Including, MPD Manifold Equipment (manifold, buffer tank, umbilical, drape hoses, sheave…) and Coriolis Meters at each HP Mud Pump

- The installation of a second BOP (Blow Out Preventer). Including BOP test stump, Test HPU and Accumulator assemblies, Pod Workshop

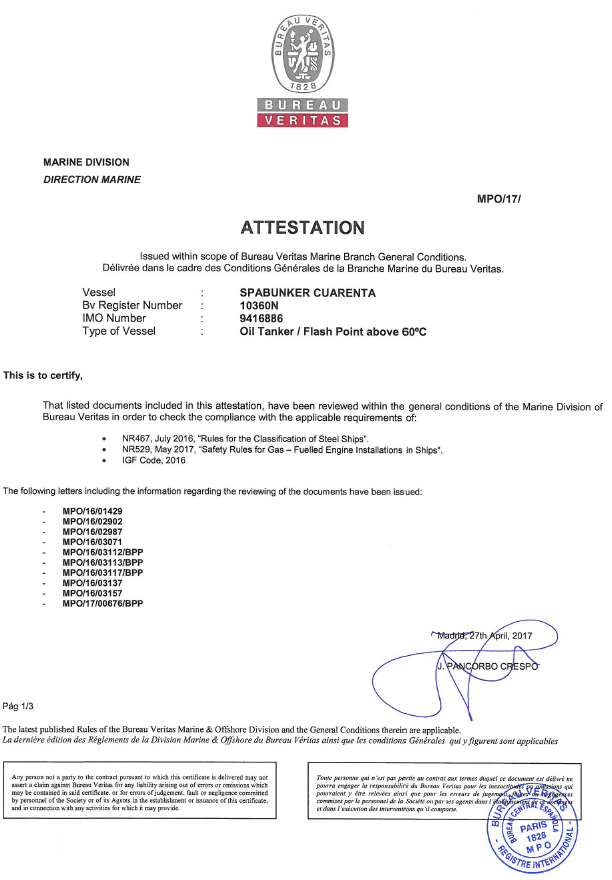

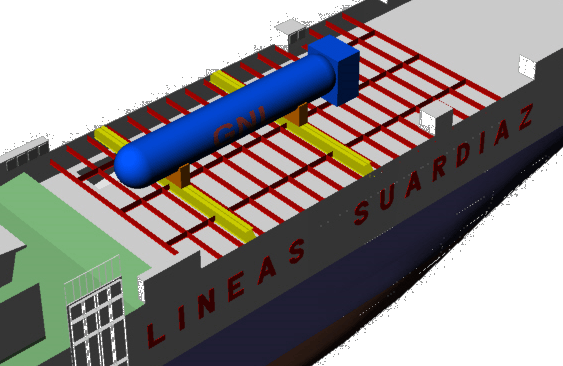

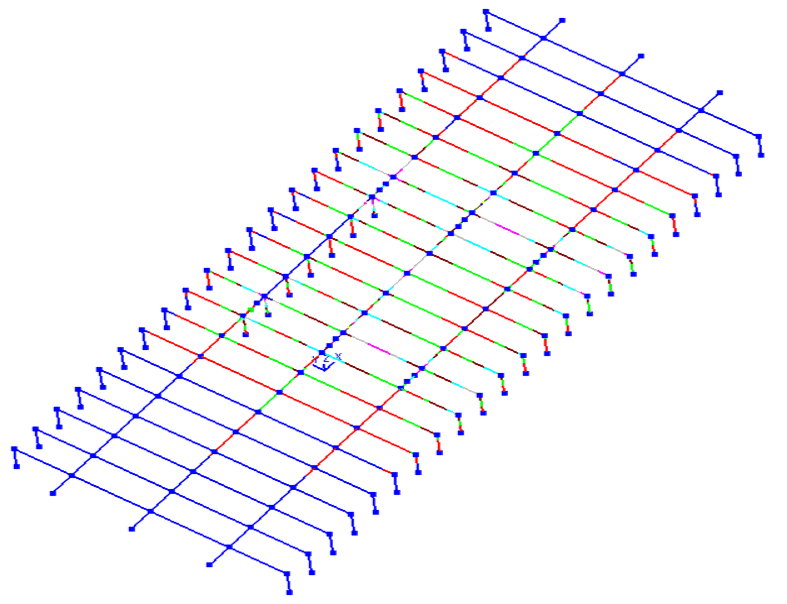

PROJECT: Multi-product Bunker Ship Retrofitting HFO/GO/LNG(1.000 m³)

Concept Engineering and Basic Engineering retrofitting design of the Boluda’s bunker fuel barge to LNG Bunkering. Gas fuelled

- LNG capacity Analysis. LNG Bunker Optimization

- LNG tanks arrangement Design

- Stability and Visibility Design

- Structural Design

- LNG Bunkering Design

- NG fuel supply Design

- Vessel main systems retrofitting Design

- LOA: 73.50 m

- Beam: 16.25 m

- Design Draft: 5.40 m

- Service Speed: 12 kn

The Project development is part of the European

GAINN4MOS project

Class Notation:

I Hull, Mach, Oil Tanker ESP / Flash point above 60, unrestricted navigation, AUT-UMS, LNG Bunkering Ship, Gas Fuelled

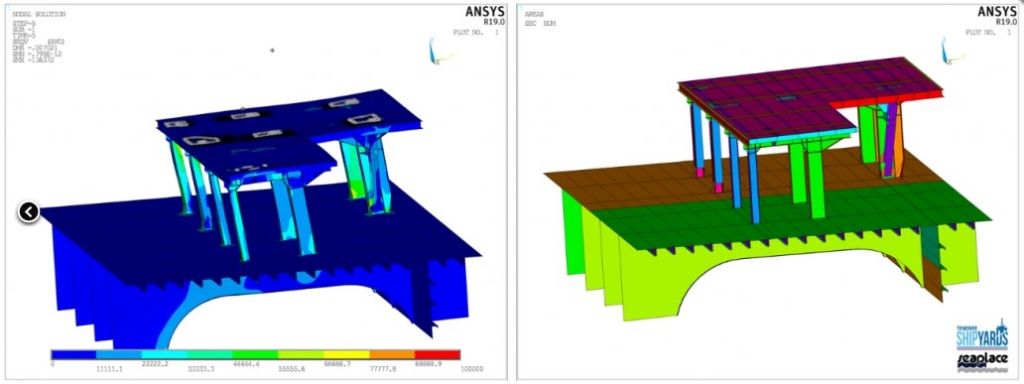

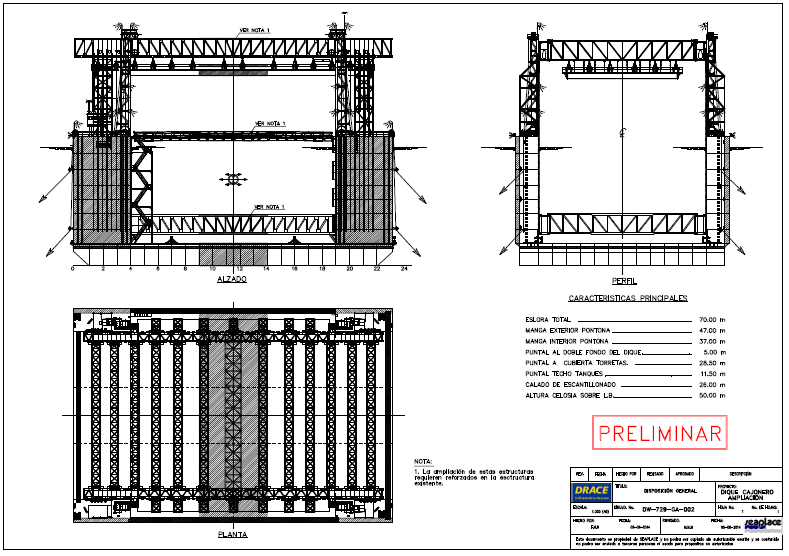

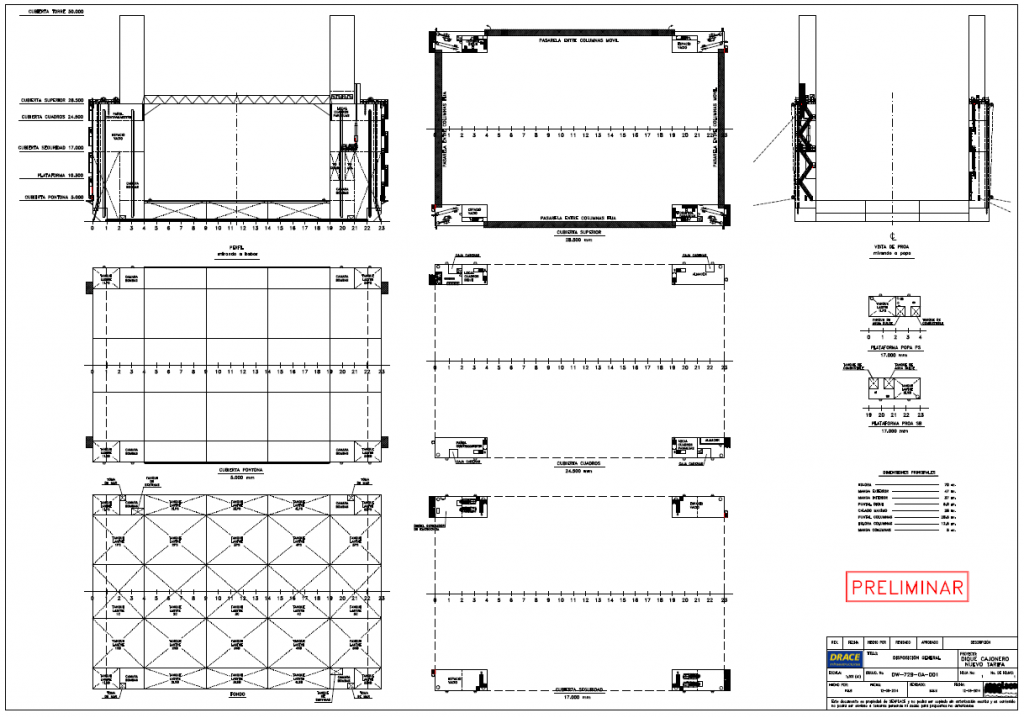

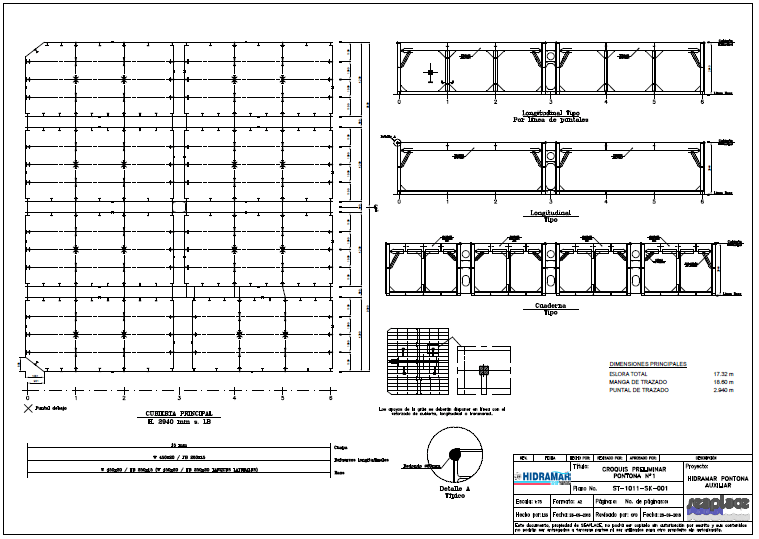

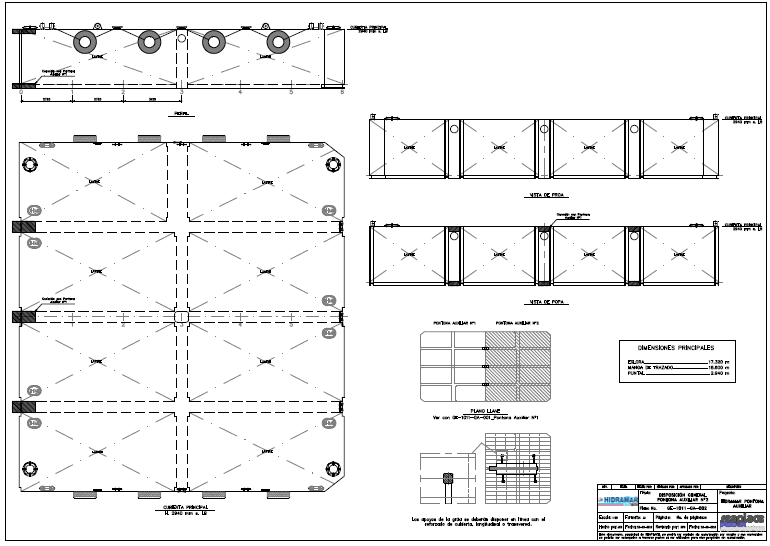

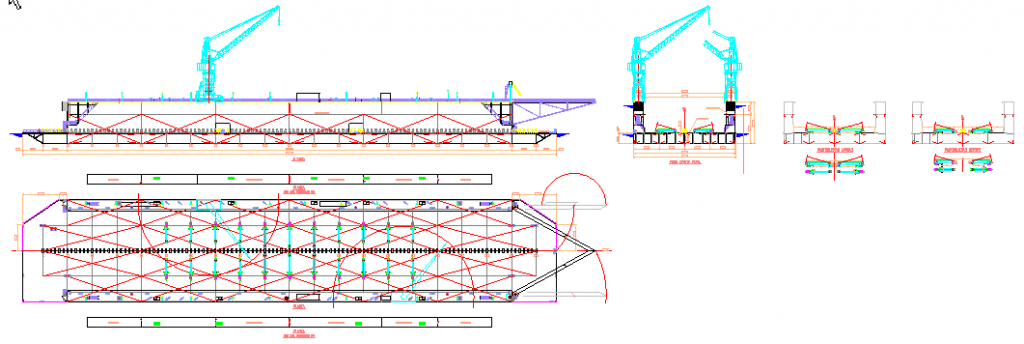

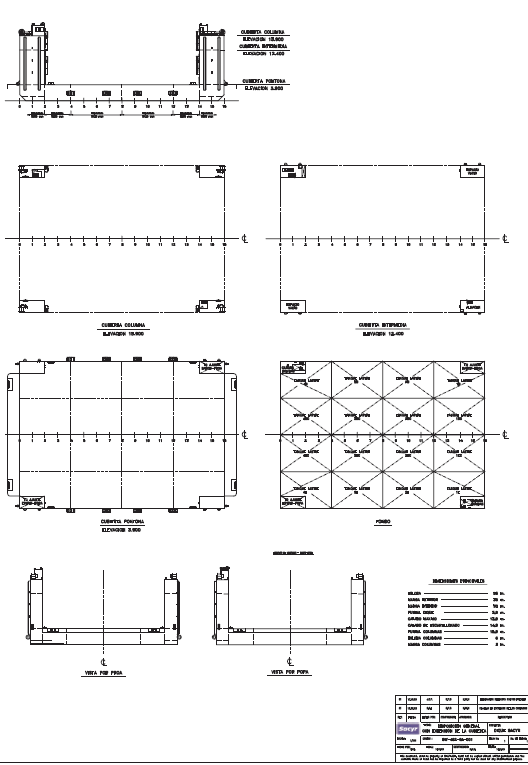

PROJECT: TARIFA I- Floating dock for offshore wind gravity unit construction

PROJECT: RoRo GRAN CANARIA

Conceptual Engineering Retrofitting of a RoRo to Gas fuelled (HFO/LNG)

- RoRo Operational Analysis

- LNG tanks sizing and arrangement on board

- Stability and visibility analysis

- Structural Analysis

- NG fuel supply Analysis

- LNG Bunkering Analysis

- Vessel main systems retrofitting Analysis

- Safety Analysis

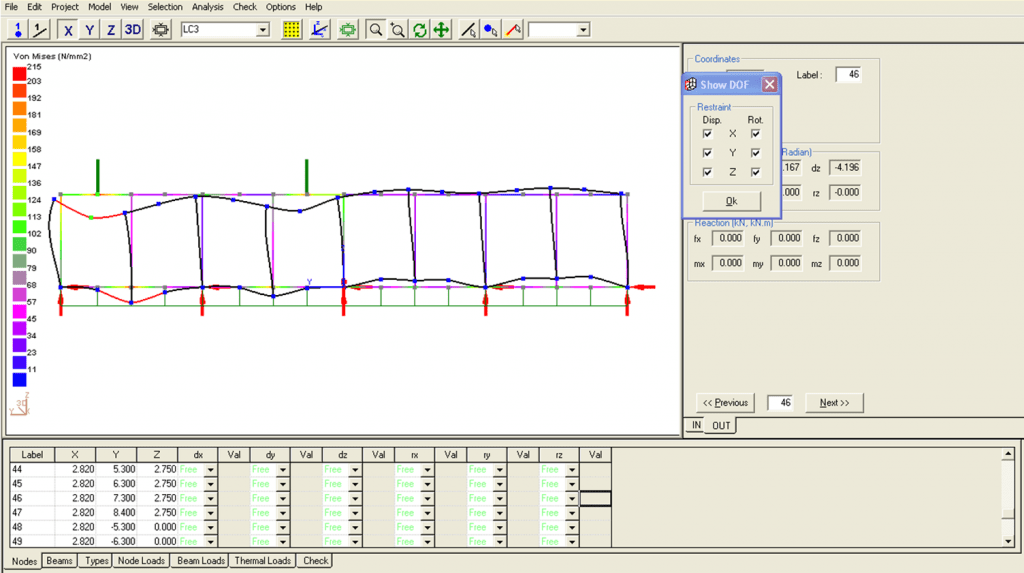

PROJECT: 2500 ST Crane Vessel

Analysis of the conversion of an Artic Supply Vessel into a 2500 ST Crane Vessel:

- On-site vessel inspection

- Documentation inspection

- vStructural Analysis for the installation of a 2500 ST crane

- vNaval Architecture calculations

- vDefinition of new systems, retrofitting of existing systems and list of equipment

- Design of the accommodation and mooring system